Why is Textile Innovation Necessary?

The textile industry contains health and sustainability concerns at every step of its supply chain: from pesticides in agriculture, toxic chemicals used in dyes and finishes, to microplastics that have been found in our waterways, food, and even within the human bloodstream. Polyester, a fossil fuel based filament, makes up 50% of fiber production today. It has completely transformed the textile market since it launched in the 1950’s by outperforming historically used natural fibers and contributing to carbon emissions and toxics within our homes and environment.

Polyester, a fossil fuel based filament, makes up 50% of fiber production today.

Innovations within the textile industry are essential to achieve fibers with similar (or new) performance properties to synthetics without the harmful effects. At HML, we keep our eye on the forefront of materials currently in research and development to identify the healthier materials that will be available in the near future.

Exhibition at the Future Fabrics Expo in Chelsea, New York

What are Future Fabrics?

Future Fabrics can be defined as (but not limited to):

- - new fibers or materials (such as from seaweed);

- - new dyes and finishes (such as from bacteria);

- - a return to natural fibers or dyes (such as linen and hemp grown with regenerative practices);

- - or new circular systems (such as upcycling textile waste into fiber).

The Future Fabrics Expo organized by The Sustainable Angle has been hosted in London for over 10 years. The expo came to New York for the first time to showcase over 5000+ materials in 2023.

Materials shown at the Future Fabrics Expo are vetted and identified as sustainable and responsibly sourced based on criteria addressing: water use, energy, waste, biodiversity, chemicals, animal welfare, traceability, and social justice. Their criteria is closely aligned with our work at HML. Our vetted Textiles Material Collection includes healthier and more sustainable textiles that address the footprints of fiber cultivation and production as well as the toxicity of applied treatments.

The expo encourages manufacturers and designers to select material alternatives to existing toxic petrochemical materials. They prioritize textiles that are transparent, compliant with the ZDHC restricted substance list, and demonstrate the removal of petrochemicals from printing, dyeing, finishing, and cleaning processes. Each material included a tag detailing sustainability information and relevant environmental certifications. It was encouraging to see a curated collection offering transparency of material composition.

What did we see?

A display of plant material, natural and bacterial dyes.

Sages textile samples with natural dyes from food waste.

Entrance to the Future Fabrics Expo.

OnceMore's regenerated textile process for blended fibers, which are mixed with cellulose pulp from FSC certified forests.

A leather alternative called BeLEAF uses a chrome-free tanning process.

Typical textile dyes and pigments contain a multitude of toxics. HML is interested in natural dyes and pigments that originate from plants. The Nature Coatings BioBlack TX pigment is a direct replacement for toxic, petroleum-based black pigment dispersions. It is made of a proprietary black pigment made from wood waste from sustainably managed sources. It is water-based and certified as 100% bio-based from USDA Biopreferred. Refer to our Natural and Healthy Material Collection on Plants for more information.

A new black pigment made from wood waste will replace petroleum based pigments.

Nature Coatings’ BioBlack TX pigment printed on a cotton textile.

HML is also interested in new biodegradable natural fibers. Kelsun by Keel Labs is a compostable yarn made of readily abundant biopolymers from seaweed. The fiber is still in development and is anticipated to be available on the market within three to five years. It will be a sustainable, closed-loop alternative for the apparel and footwear industries. At the expo, Keel Labs debuted a Kelsun blend knitted material sample.

A compostable yarn made of seaweed will be used in apparel and footwear in 3-5 years.

A sample of knitted Kelsun fiber by Keel Labs.

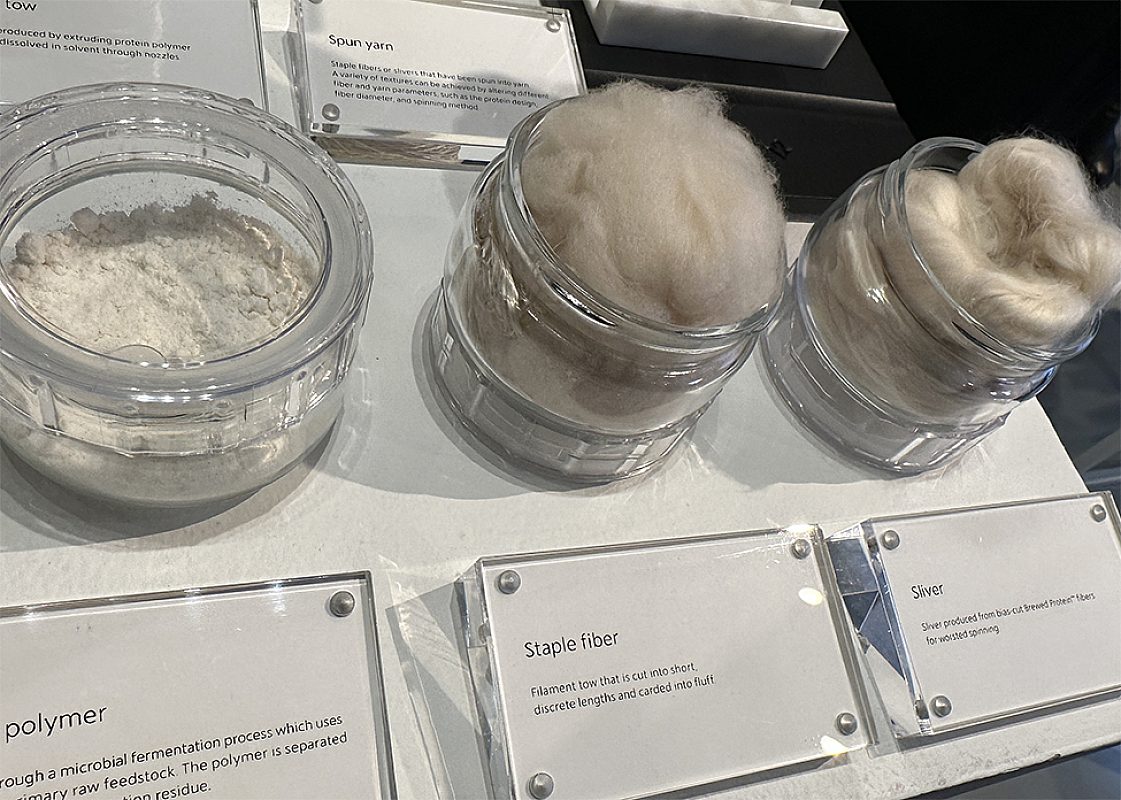

Spiber harnesses microbial fermentation of sugars to grow silk protein and extrude filamentous fibers. Their Brewed Protein™ is commercially produced in Thailand using sugarcane feedstock and will begin production in the US in 2024 with corn feedstock. The fiber has been demonstrated to biodegrade in soil. Brewed Protein™ has been debuted in fashion collections by brands like Pangaia and North Face, but has yet to be developed for the interiors market.

A fermentation process of corn and sugarcane produce a biodegradable fiber called “Brewed Protein™”

Process of Spiber’s Brewed Protein™ fiber.

What did we learn?

It is important that material health and ingredient transparency remain at the forefront of materials innovation. It was encouraging to see physical samples showing progress from years of development, but there is still a lot of work to be done within the textile industry to achieve circular, regenerative materials and systems.

Many new materials are still scaling and are only available as blends with cotton or lyocell due to their high costs of production. Others are still in the development phase and will not be available at scale for another three to five years. We were hoping to find suppliers of bast fibers like hemp and linen grown in the US. We’re looking for more natural fibers that are grown and processed locally. And, to make a real shift to sustainable production, they need to be offered at lower prices to be competitive with synthetic counterparts. New textile innovations tend to be developed within the fashion industry first before entering the interiors market. We hope to see more healthier, PFAS-free, bio-based finishes developed to meet fire codes. You can reference our HML Textile Guides and Material Collections for more information and insights related to material health.

Read More

Join Our Academic Network

Get Access to our carefully researched and curated academic resources, including model syllabi and webinars. An email from an academic institution or a .edu email address is required. If your academic institution does not use .edu email addresses but you would like to join the network, please contact healthymaterialslab@newschool.edu.

Already have an account? Log in