A collaboration between BIG’s Model Making Center in their Copenhagen Studio and the Lab in NY is researching products and methods to make Architectural Model Making a craft that avoids hazardous substances and helps set an agenda for healthier building practices.

Two members of the HML team (Alison Mears and Leila Behjat) visited BIG Studio during a stay in Copenhagen for a Building Green Conference in November 2021. We began the meeting with Katrine Juul and sustainability team members from BIG IDEA. We then toured the Model Making Center, managed by Artemis Antonopoulou. The Center’s Model Making Leadership has taken steps to enhance health and sustainability in the space by installing air filter systems and adopting policies to reduce material waste.

The BIG Studio in Copenhagen

Members of the BIG Sustainability Team, the Model Making Center and HML at BIG Studio, Copenhagen

BIG Model Making Center

Artemis Antonopoulou and Alison Mears in the BIG Model Making Center

The initial exchange sparked a collaboration that includes raising awareness of hazardous substances and establishing alternatives to products commonly used in Model Making, such as petrochemical-based foams, glues and paints.

“If we cannot create sustainable models, how can we create sustainable buildings?”

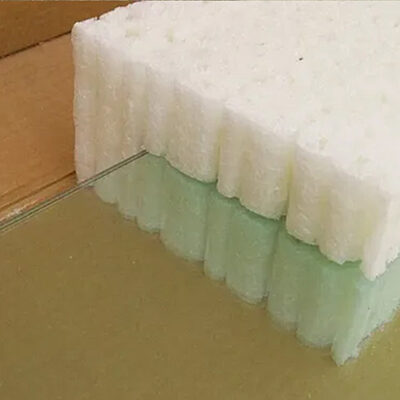

In the past, Designers and Architects had fixed ideas on the presentation of a design idea using readily available, inexpensive model-making materials. Consistent with Modern Architecture’s stylistic preferences for pristine white models, many architects have wire-cut white styrofoam to represent building volume and used a range of plastic board products to represent walls and openings. When laser cutters are used, the tendency is to use materials that reduce burn or bending marks. These practices are common and deeply rooted in Model Making. Often the time crunch in a project prevents the exploration of alternative, sustainable materials and making practices. Today, as we confront the climate crisis, we are moving from petroleum-based, toxic products to more bio- and mineral-based, low embodied and benign materials in our architectural construction practices. So why not explore these better materials in model-making?

The ongoing investigation with BIG is twofold: finding healthier alternatives to products commonly used in model making on the one hand; on the other, offering and encouraging model-making methods with the adoption of principles of designing for disassembly. The explorations include using mechanical joining, and the incorporation of traditionally unconventional product options with the goal of avoiding harmful foams, glues and finishes and reducing waste.

models in the making: tabs reduce the need for adhesives

models in the making: magnets reduce need for adhesives

designing with joints avoids the use of adhesives

In monthly team meetings, the project collaboration aims to elevate Model Making to be a gateway to healthier architectural design work. Experience shows that the incorporation of better practices in model prototypes brings designers on board: “Everything we’ve managed to change has come through making a sample”, is the observation of Phillipa Seagrave, a Lead in the Center.

An awareness of health hazards in products, and ingredient disclosure for transparency are crucial at the building scale. Establishing frameworks for healthier Best Practices starts with a healthier Project Model.

Sustainable Model Making

26 products

About Our Collections

The goal of our collections is to help promote transparency in the material ingredients of building products by fostering knowledge and awareness of products and materials for which life-cycle information is available, and that have environmentally, economically, and socially preferable life-cycle impacts.

Keep an eye out for the following symbols:

A Healthier Affordable Building Product

Products with the designation of "Healthier & Affordable" were specified and installed in at least one of our Case Studies of healthier affordable housing.

Available at the Donghia healthier Materials Library

The Donghia healthier Materials Library library is open to Parsons student and faculty. Learn more about access and opening hours here.

Low Embodied Carbon

“Embodied Carbon” is the total amount of carbon emitted during the process of making a material. *HML refers to a manufacturer's EPD to determine whether a product's A1-A3 carbon emissions falls within HML's threshold for Low Embodied Carbon.

New Product

This product has been added to the collection within the past six months.

Product in Development

Products with this designation identify they are currently scaling or only available in markets outside of the building industry. they could be experimental or in use in capsule collections.

Available in the EU

Products with this designation are currently available only in the European Union and identified as being an exemplary healthy option in the respective product group.

Ingredient Disclosures

There are several ways of evaluating a material’s health that we include with product information. Disclosures are reports by manufacturers about product ingredients, impacts, or other attributes.

Key Disclosures include:

Health Product Declaration (HPD)

A voluntary technical specification for reporting information on product contents and associated health information, intended to be the health-analogue to Environmental Product Declarations (EPDs).

Declare Label

Declare is a transparency platform and product database that answers three questions:

1. Where does a product come from?

2. What is it made of?

3. Where does it go at the end of its life?

Environmental Product Declaration (EPD)

A standardized format for communicating the environmental effects associated with a product’s raw materials extraction, energy use, chemical makeup, waste generation, and emissions to air, soil, and water.

Safety Data Sheet (SDS)

A reporting format that provides basic information about a material’s chemical ingredients, the potential safety hazards to installers, and recommended practices for installation.

USDA Certified Biobased Product Label

Managed by the U.S. Department of Agriculture (USDA), the goal of the BioPreferred Program is to increase the purchase and use of biobased products.

Other

| Category | Sub-category | Manufacturer | Product | Ingredient Disclosures | |

|---|---|---|---|---|---|

| Dimensional Surface | MDF | Roseburg | Roseburg: Medite II MDF | HPD Declare EPD SDS |

Roseburg’s Medite II MDF is a high strength, MR30 grade moisture-resistant, multi-use Medium Density Fiberboard made from up to 92% of recycled cellulose content. Medite II has no added formaldehyde (NAF), is SCS Certified for 92% of pre-consumer recycled content, CPA ECC Sustainability Standard Certified, and Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) certified. Architects and designers can earn LEED v4 Low Emitting Materials Credit Support project credits. Roseburg's Medite II contains less than 7% isocyanate resin. Currently, this is a healthier alternative to most MDF's with as much as 10% resins and more, or use phenolic resins or added formaldehyde. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Dimensional Surface,

MDF

Material composition*Wood Fiber 82-97%, Water 1.8-8%, Isocyanate Resin 0.75-7.35%, Benzene 1-isocyanato-2[4-isocyanateophenyl)methyl] 1%, Borate Flame Retardant <1%, Urea <1%, Slack Wax <1%, Undisclosed <1%, Octadecanoic Acid <1% *as reported by the manufacturer

ManufacturerRoseburg

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

Additional Documents |

| Dimensional Surface | Plywood | Columbia Forest Products | PureBond Classic Core® Plywood | HPD Declare EPD SDS |

Classic Core® is a combination core panel construction where cross bands of thin MDF are utilized in place of veneer cross bands. Classic Core® can be manufactured with bonded crossbands which do not contain added formaldehyde. PureBond Classic Core® may contribute to LEED® 2009 credit IEQ 4.4 and conforms to CARB II exempt emission requirements called for in LEED V4. It contains 95% Biobased Content and has been awarded the USDA Certified Biobased Product Label in the BioPreferred® Program. Used in Healthier Affordable HousingIn Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Dimensional Surface,

Plywood

Material composition*Veneer: Wood; Decorative veneer: Wood; adhesive: Polyvinyl Acetate; Water; Defatted Soy Flour; Magnesium oxide (MgO); Hexanedioic acid, polymer with N-(2-aminoethyl)-1,2-ethanediamine and (chloromethyl)oxirane; Monopotassium Phosphate; Glycerin; Corn Starch; Borax; Calcium hydroxide (Ca(OH)2) *as reported by the manufacturer

Available Sizing4’x 8’, 4’x 10’ Panels - 1/2”, 5/8”, 3/4”, 1” and 1-1/4” thickness COLORSVariety of wood species ManufacturerColumbia Forest Products

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

FSC Certification

Rainforest Alliance Certification

Contributes to LEED credits

USDA Certified Biobased Product Label

Additional Documents |

| Dimensional Surface | Plywood | Columbia Forest Products | PureBond Hardwood Plywood | HPD Declare EPD SDS |

Columbia Forest Product's PureBond hardwood plywood is formaldehyde-free, and is instead made with a soy-based binder. This North American-made product is also cost-competitive with standard plywood products, making it a fantastic healthier alternative. It contains 95% Biobased Content and has been awarded the USDA Certified Biobased Product Label in the BioPreferred® Program. Used in Healthier Affordable HousingIn Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Dimensional Surface,

Plywood

Material composition*Wood Dust 95.65%, Other components below the reportable levels, (the specific chemical identity and/or percentage of composition has been held withheld as a trade secret) <1% *as reported by the manufacturer

Available Sizing2’x 4’, 2’x 8’, 4’x 8’, 4’x 10’ Panels - available in standard thickness COLORSVariety of wood species ManufacturerColumbia Forest Products

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

FSC Certification

Rainforest Alliance Certification

Contributes to LEED credits

USDA Certified Biobased Product Label

Additional Documents |

| Sealer / Surface | Oil_Linseed | Rubio Monocoat | Oil Plus 2C | HPD Declare EPD SDS |

Rubio Monocoat's Oil Finish is a healthy option for wood finishing. A single layer of this product will protect wood from water, heat, and daily wear and tear trough molecular binding with the wood fiber. It is great for use on hardwood flooring, wood furniture or any other wood product. This product creates a finish that is easy to maintain, and it is free of VOCs and solvents. *Note: This product is sold in two components. Component A is the oil finish and Component B is an accelerator, which speeds the drying process. Although it helps with convenience, we recommend the product to be used without the accelerator as it contains isocyanates, listed as asthmagens and potential carcinogens by OSHA In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Sealer / Surface,

Oil_Linseed

Material composition*Linseed Oil, Carnauba Wax, Beeswax, Plant Based Pigments *as reported by the manufacturer

Available SizingAvailable in 130 mL, 390mL, 1.3 L, and 3.5 L sizes COLORSAvailable in 40 colors ManufacturerRubio Monocoat

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

GREENGUARD | Gold

Eurofins Gold Indoor Air Comfort

Additional Documents |

| Packaging | Starch | Paperfoam | Paperfoam | HPD Declare EPD SDS |

Paperfoam is a packaging material made from starch, FSC-certified cellulose fibers, water and a proprietary pre-mix. It contains 88% biobased content, according to Bioprefered.gov. It can be recycled within the paper stream and is home compostable. As declared by the manufacturer, the material, including the pre-mix, is free from formaldehyde, solvents, PFAS, flame retardants, bisphenols, phthalates, and heavy metals. It can be injection moulded and embossed. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Packaging,

Starch

Material composition*Starch 70%, Cellulose fibers 12% , Proprietary Pre-mix 18% *as reported by the manufacturer

ManufacturerPaperfoam

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

USDA Certified Biobased Product Label

|

| Packaging | Polylactic Acid (PLA) | Synbra Technology | BioFoam | HPD Declare EPD SDS |

BioFoam is a plant-based alternative to traditional EPS foams. This product is made from PLA (polylactic acid), a type of polymer derived from the production of sugar cane. Beads of PLA (BioBeads) are made through the fermentation process of the sugar cane, and then are expanded with CO2 into EPS-like pearls. BioFoam is the first CO2 neutral foam in the world, and is Cradle to Cradle Silver Certified. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Packaging,

Polylactic Acid (PLA)

Material composition*Polylactic Acid (PLA) *as reported by the manufacturer

COLORSOff-white beads ManufacturerSynbra Technology

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

Cradle to Cradle | Silver

Additional Documents |

| Sealer / Surface | Oil_Linseed | Viking | Viking Linseed Oil Wax | HPD Declare EPD SDS |

The Viking Purified Linseed Oil Wax is 100% natural, combining the Viking Purified Raw Linseed Oil and beeswax. It is made in the USA, food-safe and contains no petrochemical additives. Ideal for wood surfaces, including unfinished wood, and can also protect metal, ceramic, tile, and rubber. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Sealer / Surface,

Oil_Linseed

Material composition*100% Viking Purified Raw Linseed Oil and Beeswax *as reported by the manufacturer

Available Sizing16 oz, 32 oz ManufacturerViking

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Lighting | Mycelium | MushLume Lighting | MushLume Lighting Collection | HPD Declare EPD SDS |

The MushLume Lighting Collection consists of pendants, sconces, and table lamps and is literally grown using Ecovative's MycoComposite - a combination of mycelium and regionally sourced non-food agricultural waste. After the mycelium has fully matured, the lampshades are de-molded, dried, and heated, creating a 100% biodegradable lampshade. MycoComposite is biodegradable, naturally flame resistant, and water resistant. Last UpdatedJanuary 13, 2026 Categories

Lighting,

Mycelium

Material composition*Mycelium (binder), hemp (substrate), flour (nutrition) *as reported by the manufacturer

Available SizingVaries ManufacturerMushLume Lighting

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Packaging | Mycelium | Ecovative | Mushroom® Packaging | HPD Declare EPD SDS |

Mushroom® Packaging is made from Ecovative MycoComposite, which is biodegradable, naturally flame resistant, and water resistant. The MycoComposite material is grown and dried within 7 days for ready-to-use packaging. It is 100% home-compostable and has a Class A Fire Retardant rating. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Packaging,

Mycelium

Material composition*Mycelium (binder), hemp (substrate), flour (nutrition) *as reported by the manufacturer

Available SizingCustom designs COLORSNatural ManufacturerEcovative

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

Additional Documents |

| Textile | Wool | FabriTRAK | FabriFELT™ | HPD Declare EPD SDS |

FabriFELT™ is made entirely from sheep's wool. The material is suitable for walls and ceilings, and contributes to sound absorption. FabriFELT™ is disclosed through its DECLARE label. The product is Red List Free, suitable for LEED v4 projects. As a natural material, felt can be recycled: the manufacturer will take it back for recycling or via general textile recycling pathways. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Textile,

Wool

Material composition*100% Sheep's Wool *as reported by the manufacturer

COLORS23 Colors ManufacturerFabriTRAK

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Textile | Wool | Filzfelt | 5mm Wool Design Felt | HPD Declare EPD SDS |

Available for furniture, fashion, and vertical surface applications, this felt product is a high-quality wool material. It contains no formaldehyde, and is 100% VOC free. Filzfelt's wool holds the Oeko-Text Standard 100 certification. Sheep's wool contains lanolin, a thin waxy coating on the fibers which makes it naturally water and soil resistant. Plus, because wool retains moisture in every fiber, it resists flame without chemical treatment. It can also be 100% biodegradable as it is a natural fiber. This product can be customized with a flame retardant treatment. We advise selecting untreated textiles whenever possible. *Ask about budget-friendly "off-cuts". In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Textile,

Wool

Material composition*99% Merino or Karakul Wool, 1% dye (see HPD for dye composition) *as reported by the manufacturer

Available Sizing70 3/4"/180 cm wide COLORS66 Colors ManufacturerFilzfelt

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

Oeko-Tex®

|

| Sealer / Surface | Oil_Hemp | The Real Milk Paint | Hemp Oil | HPD Declare EPD SDS |

Hemp oil is a healthier finish and works particularly well on wood. The Real Milk Paint’s Hemp Oil is free of additives, preservatives, solvents, and VOCs. It is thinner than tung oil, making it easier to apply without the addition of a solvent. However, hemp oil is less durable and waterproof than tung oil. Hemp oil is food safe and works especially well on lightly used items. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Sealer / Surface,

Oil_Hemp

Material composition*Industrial Hemp Oil 100% *as reported by the manufacturer

Available SizingAvailable in 1 oz, 8 oz, 16 oz, 32 oz, and 1 gallon bottles ManufacturerThe Real Milk Paint

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Sealer / Surface | Oil_Tung | The Real Milk Paint | Pure Tung Oil | HPD Declare EPD SDS |

Tung oil (sometimes called chinawood oil) is an all-natural hard drying wood oil that provides a tough, flexible, highly water-resistant coating or wood finish. Tung oil is available in 3 grades. The Real Milk Paint’s Pure Tung Oil is Grade 1 yellow, the highest grade available. This means that it offers faster drying, superior color, and a long-lasting finish. This product is free of VOCs and other harmful additives. Some prefer it over linseed oil because it dries faster and does not darken as much with age. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Sealer / Surface,

Oil_Tung

Material composition*Tung Oil 100% *as reported by the manufacturer

Available SizingAvailable in 1 oz (sample), 8 oz, 16 oz, 32 oz, 1 gallon, and 55 gallon bottles ManufacturerThe Real Milk Paint

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Sealer / Surface | Oil_Linseed | Allback | Purified Boiled Linseed Oil | HPD Declare EPD SDS |

Linseed Oil is a natural, solvent-free finish coating derived from flax seeds. Not only does it perform better than petrochemical alternatives - it is also much healthier. Linseed oil is free of toxics such as isocyanates and bisphenols, which are found in polyurethane and epoxy resins. Allback manufactures their Purified Linseed Oil in Sweden. Their Purified Boiled Linseed oil is a drying oil, making it ideal for a final finish on wood and metal. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Sealer / Surface,

Oil_Linseed

Material composition*Linseed Oil <99.01%, Manganese Drying Agent <0.09% *as reported by the manufacturer

Available Sizing5 Liters ManufacturerAllback

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Dimensional Surface | Hardboard | Ampersand Art | Hardboard | HPD Declare EPD SDS |

Ampersand Art’s hardboard is a healthy, sustainable option for model-making. Sometimes referred to by the trade name Masonite, hardboard is a composite wood material that’s made by compressing wood dust. Ampersand Art’s flat panel board is 1/8” thick. It is NAUF, meaning it is made without urea formaldehyde and is made from FSC certified wood. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Dimensional Surface,

Hardboard

Material composition*Wood Dust, Linseed Oil *as reported by the manufacturer

Available Sizing1/8" thick boards are available in 5x7, 6x8, 8x10, 9x12, 11x14, 12x12, 12x16, 12x24, 14x18, 16x20, 18x24, 18x36, 24x36 inch flat panels ManufacturerAmpersand Art

Additional DocumentsCertifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

Additional Documents |

| Sculpting | Beeswax | Stockmar | Modelling Beeswax | HPD Declare EPD SDS |

Stockmar’s Modelling Beeswax is a nondrying wax that warms in your hand to create a reusable molding material. The product carries an AP Seal. It was developed for use in early childhood education, and was designed to be non-toxic and safe for this sensitive audience. In addition to meeting the toxicology standards of the AP Seal, Stockmar commissions an independent residual analysis laboratory to test every batch of ingredients that they use in their products. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Sculpting,

Beeswax

Material composition*Paraffin (Microcrystalline Waxes) 64%, Beeswax 30%, Venetian Turpentine 3%, Synthetic Organic and/or Synthetic Inorganic Color Pigments >3% *as reported by the manufacturer

Available SizingAvailable in 100mm x 40mm and 240mm x 100mm sheets COLORSAvailable in 15 colors ManufacturerStockmar

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

AP Seal

|

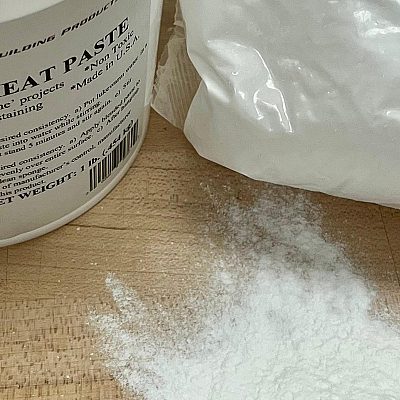

| Adhesive / Model Making | Wheat | Playbox | Wheat Paste | HPD Declare EPD SDS |

Wheatpaste is a natural, non-toxic adhesive. It has been in use for centuries and is commonly used to put up posters, make paper-mâché and collage, and for archival quality bookbinding. Playbox’s product is made from real wheat and is free of preservatives. It is sold in powder form and can be activated by adding water. Alternatively, wheat paste can be easily and inexpensively made at home. There are many DIY recipes, including this one, online. The gluten in wheat flour lends a permanent bond to wheat paste. Changing the ingredients will alter the permanence of the adhesive. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Adhesive / Model Making,

Wheat

Material composition*Starch <70%, Crystalline Silica <0.5% *as reported by the manufacturer

Available SizingAvailable in 1 lb. and 3 lb. buckets COLORSWhite, dries clear ManufacturerPlaybox

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Dimensional Surface | Solid Wood | Midwest Products | Basswood | HPD Declare EPD SDS |

Sustainably harvested basswood is a healthy choice for model-making. Midwest Product’s basswood is harvested in Northern Michigan and Wisconsin, making it a preferable domestic wood. Last UpdatedJanuary 13, 2026 Categories

Dimensional Surface,

Solid Wood

Material composition*Basswood 100% *as reported by the manufacturer

Available SizingAvailable in a range of sizes, in scale lumber and sheets ManufacturerMidwest Products

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Adhesive / Model Making | Polyvinyl Acetate (PVA) | Dick Blick Art Materials | White Glue Stick | HPD Declare EPD SDS |

Blick's Glue Sticks dry clear and create a permanent bond. They are suitable for use on paper, cardboard, and fabric. This product has an AP certification from ACMI, indicating it has been evaluated by medical & toxicological experts as non-toxic. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Adhesive / Model Making,

Polyvinyl Acetate (PVA)

Available SizingAvailable in 0.28 ounce, 0.70 ounce, and 1.41 ounce sticks COLORSWhite, Purple ManufacturerDick Blick Art Materials

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

AP Seal

|

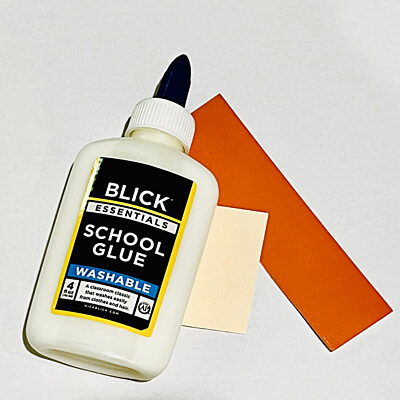

| Adhesive / Model Making | Polyvinyl Acetate (PVA) | Dick Blick Art Materials | Washable School Glue | HPD Declare EPD SDS |

Blick's Multi-Purpose White Glue works on both porous and non-porous materials. This product has an AP certification from ACMI, indicating it has been evaluated by medical & toxicological experts as non-toxic. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Adhesive / Model Making,

Polyvinyl Acetate (PVA)

Available SizingAvailable in 4 ounce, 8 ounce, 16 ounce, and 128 ounce bottles COLORSWhite ManufacturerDick Blick Art Materials

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

AP Seal

|

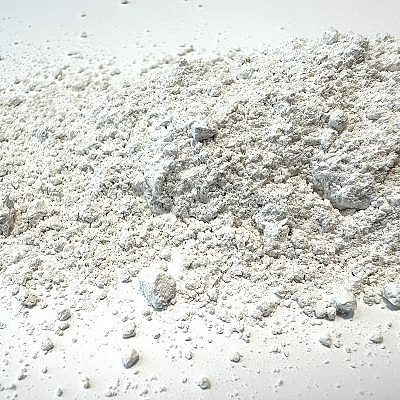

| Pourables and Aggregates | Plaster | DAP | Plaster of Paris | HPD Declare EPD SDS |

Plaster of Paris, also known as gypsum plaster, is a healthier choice for casting materials. DAP's Plaster of Paris is made from gypsum, limestone, and quartz. It sets in 20-30 minutes without shrinking and is intended for interior use. This product is ideal for hobby, molds, and casts. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Pourables and Aggregates,

Plaster

Material composition*Plaster of Paris 60-80%, Limestone 10-30%, Quartz 0.5-1.5% *as reported by the manufacturer

Available Sizing4.4 lb. box of dry plaster COLORSWhite ManufacturerDAP

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

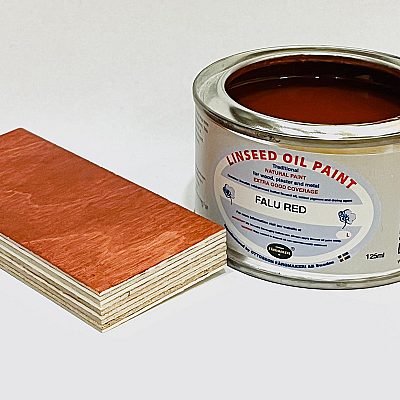

| Paint / Biobased | Linseed Oil | Ottosson | Linseed Oil Paint | HPD Declare EPD SDS |

Linseed oil paint offers a healthy, durable alternative to acrylic products. Ottosson’s product is manufactured at their facility in Genarp, Sweden, which was established in the late 1980s. The technique used in making their paints, however, dates back to the 16th century. Cold-pressed raw linseed oil and natural pigments are ground in a triple-cylinder mixer, incorporating the pigments evenly into the linseed oil. The result is a linseed oil paint that creates a breathable, easy to maintain surface that doesn’t peel or bubble up. *NOTE: Ottosson Linseed Oil Paints contain zinc oxide, a natural fungicide. It adds hardness to the paint finish and is a necessary additive in several North American climates. Zinc requires a warning label due to potential aquatic toxicity under Swedish law. When disposed of responsibly and used as directed, it poses no threat to the health of humans or the environment (as reported by Earth and Flax https://www.earthandflax.com/) In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Paint / Biobased,

Linseed Oil

Material composition*Boiled Linseed Oil 25-50%, Pigment 1-50%, Zinc Oxide 2.5-25%, Zirconium, dipropylene glycol iso-Bu alc. neodecanoate propionate cobalt complexes <0.01% *as reported by the manufacturer

Available SizingAvailable in 4 ounce, 1 Liter, and 3 Liter buckets COLORSAvailable in a wide range of colors ManufacturerOttosson

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Packaging | Corn | Temperpack | Green Cell Foam | HPD Declare EPD SDS |

Made primarily from U.S. grown, non-GMO cornstarch, Green Cell Foam is a healthier and more environmentally friendly alternative to petroleum-based foams. This material is compostable, biodegradable, and water soluble. Its manufacture requires 70% less energy and generates 80% less greenhouse gas than traditional foams. In Donghia Materials Library

Last UpdatedJanuary 13, 2026 Categories

Packaging,

Corn

Material composition*Corn Starch >90%, Water/Proprietary Additives/Processing Aids 1-10% *as reported by the manufacturer

Available SizingAvailable in 1/4" and 1/2", with variable lamination thickness options COLORSAvailable in a range of colors ManufacturerTemperpack

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Pourables and Aggregates | Sugar | Simi Cakes and Confections | Isomalt | HPD Declare EPD SDS |

Isomalt is a product that is made by heating beet sugar, reducing it to disaccharide, then hydrogenating it using a catalytic converter. The end result is a sugar-like substance with lower levels of glucose than traditional sugar. Used most commonly in cake decorating, isomalt has the potential to replace resins or acrylic in model making. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Pourables and Aggregates,

Sugar

Material composition*Beet sugar *as reported by the manufacturer

Available Sizing6 ounces COLORSAvailable in a range of colors ManufacturerSimi Cakes and Confections

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Paint / Mineral | Lime Casein | The Real Milk Paint | Milk Paint | HPD Declare EPD SDS |

Milk Paint is a powdered paint made from milk protein, lime, clay, and earth pigments such as ochre, umber, iron oxide, lampblack. Milk paint creates a matte, velvet, chalky finish that sticks to a majority of surfaces without priming or sanding. This product is made from 100% organic materials and is free of VOCs. In Donghia Materials Library

Last UpdatedDecember 16, 2025 Categories

Paint / Mineral,

Lime Casein

Material composition*Casein (milk protein), Hydrated Lime, Proprietary Natural Filler, Iron Oxide Pigment (% undisclosed by manufacturer) *as reported by the manufacturer

Available SizingPint, quart or gallon COLORSAvailable in a variety of colors ManufacturerThe Real Milk Paint

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

|

| Paint / Mineral | Potassium Silicate | Keim | Innostar | HPD Declare EPD SDS |

Mineral paints provide a healthier alternative to acrylic paints and primers as it is made from Potassium Silicate. They avoid asthmagens, are odorless, and are naturally mold-resistant. Keim Mineral Silica Paint has low to no VOCs. It is made from natural ingredients. This product is NaturePlus certified and has Cradle2Cradle Material Health Gold certification. The Innostar Line is a matte, scrub-rate class A finish with a coverage efficiency that allows for one primer & one paint coat only. Titanium Dioxide is being used for pigmenting, the whiter the pigment, the more titanium dioxide. Used in Healthier Affordable HousingIn Donghia Materials Library

Low-Embodied Carbon

Last UpdatedFebruary 12, 2026 Categories

Paint / Mineral,

Potassium Silicate

Material composition*Silica sol (aqueous solution) 10-15%, Polymer (polyacrylate) 2.5-5%, Titanium dioxide (white) and/or inorganic pigments 0-20%, Mineral Fillers (silicate and calcite) 25-35%, Water 25-35%, Hydrophobing agents 2.5-5%, Thickeners <1%, Stabilisers <1%, Wetting agents <1%, Defoamers <1% *as reported by the manufacturer

Available Sizing8kg or 20kg buckets COLORSVarious ManufacturerKeim

Certifications & Disclosures

Health Product Declaration (HPD)

Declare Label

Environmental Product Declaration (EPD)

Safety Data Sheet (SDS)

USDA Certified Biobased Product Label

Other

GREENGUARD | Gold

Natureplus

Cradle to Cradle Material Health | Gold

Cradle to Cradle | Silver

|

Join Our Academic Network

Get Access to our carefully researched and curated academic resources, including model syllabi and webinars. An email from an academic institution or a .edu email address is required. If your academic institution does not use .edu email addresses but you would like to join the network, please contact healthymaterialslab@newschool.edu.

Already have an account? Log in