The Donghia healthier Materials Library exhibits a range of bio-based materials organized by their primary macromolecule composition.

Looking at the molecular scale can help us understand how a material can be produced and determine its material characteristics. Further investigation is required to determine whether a material is indeed better based on its chemical structure, raw ingredients, manufacturing process, use, and end of useable life.

Sources for bio-based materials range from seaweed and collagen to starch and cellulose from agricultural byproducts.

Biomaterials exhibited at the Donghia healthier Materials Library.

How are Biomaterials Derived?

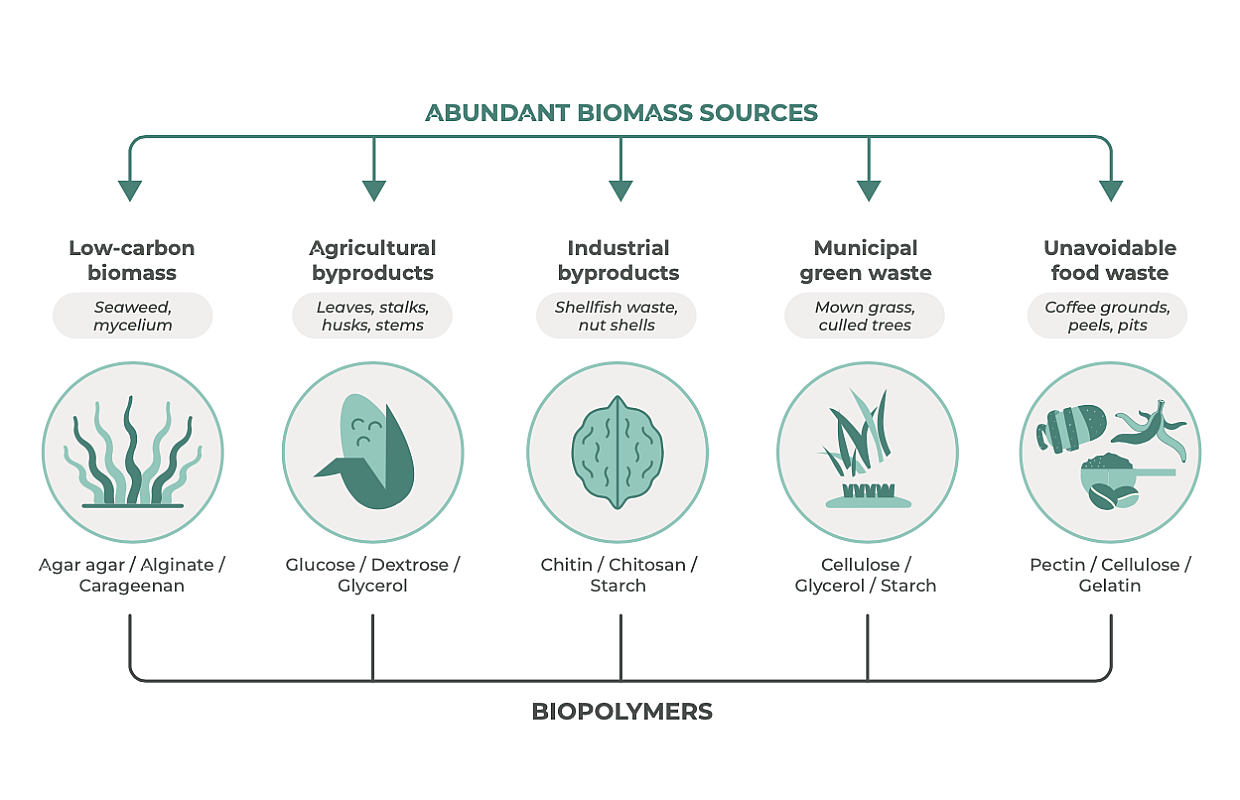

Bioplastics are a broad category derived from a variety of resources and processes to achieve diverse properties. Sources of biomaterials range from agricultural, marine, and mineral. Some raw materials may come from a current waste stream, such as agricultural or food waste, furthering the circular economy. This is preferred over products made from raw materials that use land or feedstocks otherwise used for food production.

Biomass Sources Diagram by Materiom, “What do we mean by “regenerative” materials?”

Polysaccharides are carbohydrates consisting of long chains of sugar molecules. They are the most abundant polymers derived from naturally renewable sources. Common polysaccharides are cellulose, macroalgae, chitin and starch.

Nature Coatings BioBlack TX from FSC-certified wood waste cellulose. Cellulose is naturally found in vegetable fibers and plant cell walls and was the source material for many pre-fossil fuel plastics.

TreeKind is a cellulose bio-based leather from tomato stem agricultural waste, Handbag designed by HML Material Researcher Jess Thies.

Positive Plastics offer bioplastic sample kits, such as the Sappi Symbio PLA25 from 75% PLA and 25% cellulose. PLA, a polylactide aliphatic polyester is fermented and polymerized from Starch, naturally found in most plants such as corn.

Their packaging is by Ecovative and grown from mycelium, which are the root-like structure of fungi. The filamentous networks absorb nutrients by growing through carbon-rich sources like hemp hurds, binding the material together.

Sould acoustic boards include Macroalgae, otherwise known as kelp or seaweed, a marine plant that absorbs CO2. It does not require land to grow so it won’t impact food production, and it can be combined with bioremediation efforts to enhance ecosystem biodiversity and reduce ocean acidification.

Agoprene Biofoam is 100% bio-based from Norwegian kelp and biodegradable.

Muskin is grown from the Phellinus ellipsoideus mushroom. Chitin is found in fungi and the exoskeletons of insects and crustaceans.

Vegetable Oils are lipids, fatty or oily compounds that tend not to be soluble in water. Historically, they have been used as flax-based wood finishes and linoleum flooring.

Algenisis Soleic™ foam from algae oil, 52% biobased content. Bio-based polyurethane still reacts with a bio-based oil using an isocyanate, a potential human carcinogen also linked to asthma. The isocyanates dissolve once the oils have reacted and are not present in the end product, but could still be harmful during production and installation. There is currently research into non-isocyanate polyurethanes (NIPU) which offer a healthier production process to traditional PU, but to date have yet to achieve the same material properties.

Duracryl Corques Liquid Lino is a linoleum based on vegetable and linseed oils.

Proteins are made of amino acids, of which twenty perform different functions within living organisms. Familiar protein fibers, such as sheep’s wool or silkworm silk, contain keratin and have been used as materials for centuries.

Protein based materials offer the potential for engineering new characteristics through synthetic biology. Spider silk proteins can be isolated and grown within microorganisms like yeast and e.coli. The BOLT Threads Microsilk™ is grown through this fermentation process before being spun into fibers.

Microalgae blooms are overgrowing in freshwater due to climate change. As a solution, BLOOM Materials sources microalgae for foams from toxic and harmful blooms to help remediate water bodies.

Casein is a protein found in milk for adhesives and paints. Milk paint, typically made from casein, lime, and earth pigments, were some of the earliest paints made and used by humans. Real Milk paint is a natural and non-toxic alternative to acrylic paint.

Blood bioleather is made from slaughterhouse waste, showcasing how we can make and source materials from current waste streams. Collagen is the most abundant protein in mammals and is sourced from skin, bones and connective tissues. It is typically used to make gelatin.

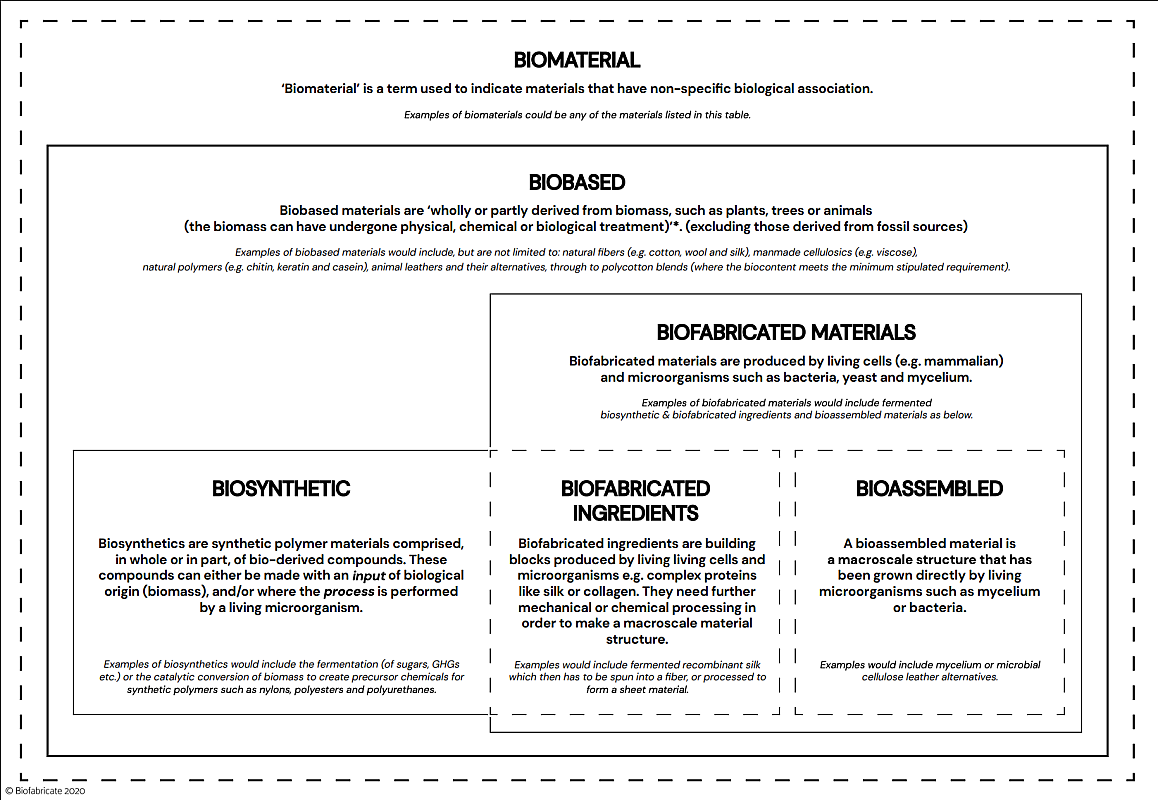

How are Biomaterials Categorized?

In a push to decouple plastic from fossil fuels, there are new biomaterials entering the market. As defined by the Biofabricate and Fashion for Good report, Biomaterials can be any material with a biological association. Specific categories are defined as follows:

Bio-based materials are “ wholly or partly derived from biomass”. Renewable biomass is a promising ingredient source to replace existing petrochemical products.

Bio-fabricated materials are grown with living cells and microorganisms such as mycelium.

Bio-synthetics or bio-based plastics, are synthetic materials created from a biological source, and typically made through the polymerization of bio-based oils.

Bioplastics can offer a lower carbon footprint. According Bioplastics For A Circular Economy,, replacing fossil fuel with sugarcane feedstocks reduces CO2 emissions by 25%. If combined with renewable energies and cutting our consumption of plastics in half, this could increase to a 93% emissions decrease.

The building industry is second to the packaging industry for total plastics consumption.

Why Biomaterials? The Problem with Fossil-based Plastics.

Since the mid-20th century, plastics have dominated a wide range of material markets due to their high versatility and performance. However, the majority of plastics are derived from fossil fuels and often include chemicals of concern. The production and recycling of plastics account for 3.4% of global greenhouse gas emissions. Plastics typically take hundreds of years to biodegrade, allowing these chemicals to leach into waterways and soil systems. We currently produce over 400 million tons of plastic waste each year and the global recycling rate is less than 10%. The building industry is the second largest consumer of plastics and uses 70% of worldwide PVC. This is a grave problem.

By 2050, there may be more plastic by weight in the ocean than fish. Traces of nanoplastics and microplastics, small pieces of plastic debris, have even been found in the human bloodstream, lungs, urine and placenta. Plastics are in nearly every product category in design materials today, including paints, finishes, packaging, flooring, and textiles. Over 54% of textile fibers are polyester. The performance of plastics has come at a high cost to both environmental and human health.

Replacing fossil-fuel sources with bio-based sources can decrease a material's carbon footprint.

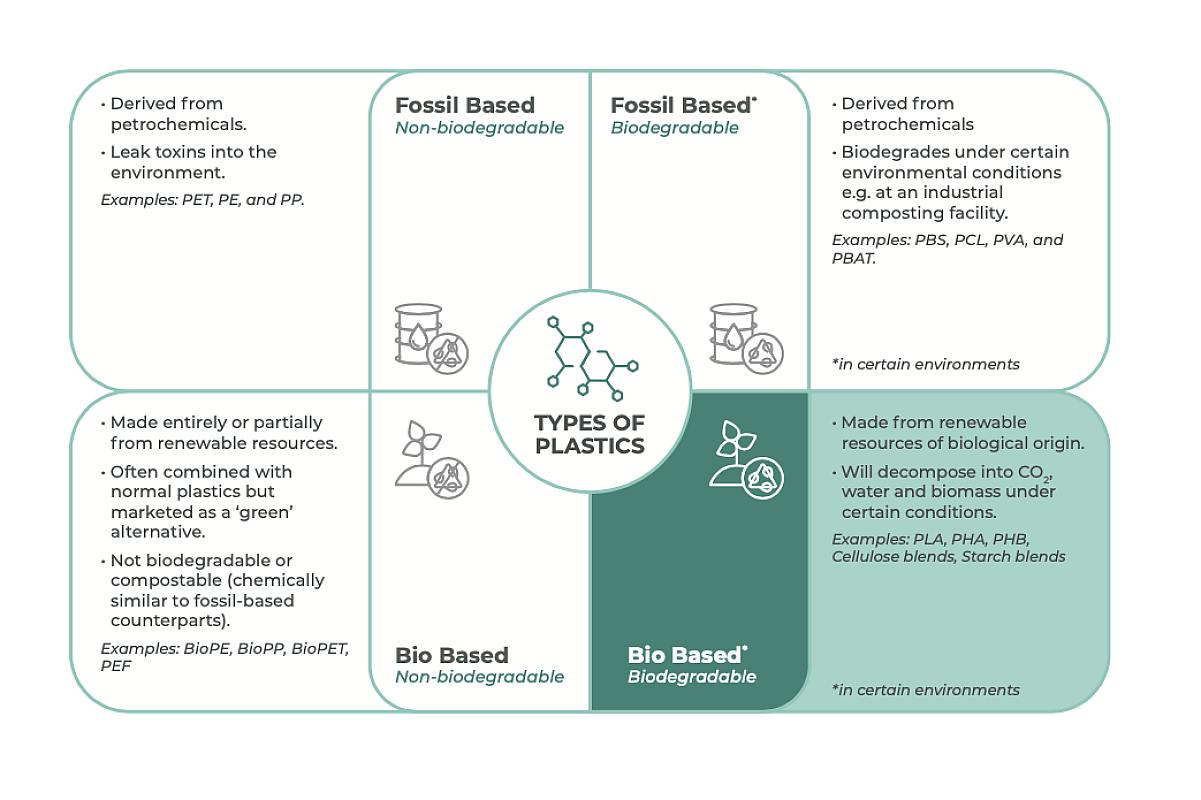

Are Bioplastics Better?

“Bio-based” does not necessarily mean bioplastics are safer or more environmentally friendly. Even when products contain bio-based content, they may still contain synthetic components or additives of concern, which can render them comparable in toxicity to petroleum-based products. The process to create bio-based polyurethane, for example, often still includes isocyanates – similar to the production of petrochemical polyurethane.

It is important to look for ingredient disclosure to fully understand health and environmental impacts. This can be challenging. In a rapidly developing field with limited available research, standards and certifications and manufacturers may want to withhold proprietary information from competitors. In many cases, the CAS# or EIN# for a petrochemical product will be identical to its innovative, plant-based replacement.

Materials with bio-based content may still contain additives of concern.

Plastic Types Diagram by Materiom, “What do we mean by “regenerative” materials?”

How do we evaluate bioplastics?

The USDA Biopreferred label declares the percentage of biobased content based on ASTM 6866 third-party testing and establishes minimum thresholds for bio-based products per product category. However, more global standards are necessary and must be established to clarify lifecycle impacts of bioplastics and other biomaterials.

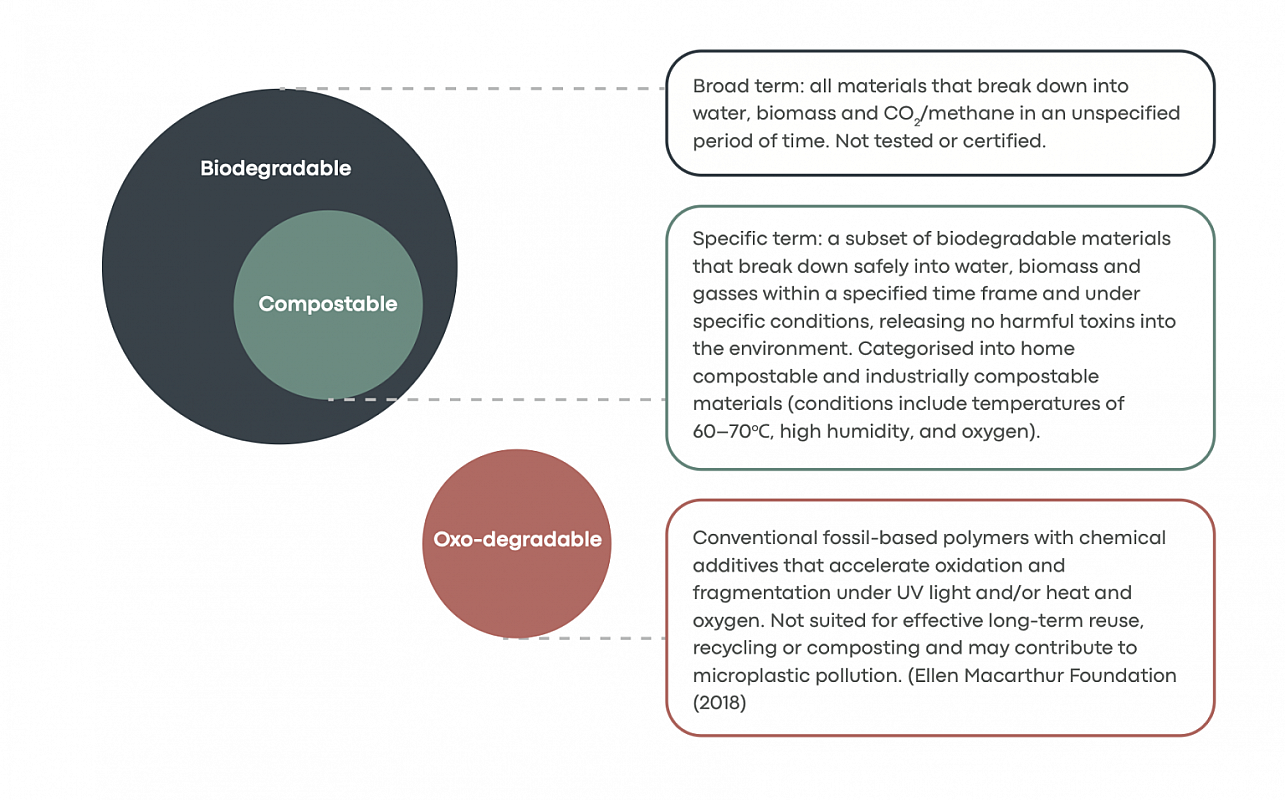

The end of life is key to evaluating a bioplastic, which should ideally be compostable. “Compostable” specifies that when a material biodegrades, it breaks down completely into natural components like oxygen and hydrogen. Biodegradable means a product can break down within soil or water by naturally occurring organisms. Biodegradability is dependent on the polymer structure and material properties and is not synonymous with bio-based materials; fossil fuel plastics can be designed to be biodegradable and bioplastics can create microplastics if they cannot break down completely.

A bioplastic like PLA, which is currently on the market, can only break down completely within industrial composting facilities. Industrial composting is not readily accessible, and does not have established systems to be viable as an end of life solution. Even when the option to industrially compost is available, bioplastics can look identical to traditional plastics, causing confusion about which product is compostable versus recyclable. Bioplastics are typically not recycled. The ASTM D6400 standard qualifies products as aerobically compostable in municipal and industrial facilities.

It is essential that new plastics are created to be compostable by microorganisms and can completely degrade without these controlled parameters.

Diagram on Biodegradable, Compostable and Oxo-degradable by Materiom, “What do we mean by “regenerative” materials?”

Can bioplastics replace petroleum based plastics?

A current challenge associated with biomaterials is scale. Natural and agricultural resources require significant infrastructure for scaling up production and manufacturers need a large market share to keep costs low for consumers. Currently, many new bioplastic products are more expensive than their fossil-based counterparts.

Removing all plastics from our economy may not be possible. Yet, replacing the most toxic plastics that contain chemicals of concern, such as PVC, with healthier, biodegradable solutions is essential. Bioplastics are a potential solution when plastic is necessary. We must still reduce our consumption of all plastics and find alternatives for single-use plastics.

How can you visit the exhibition?

The Donghia healthier Materials library is located on Parsons campus. Parsons and The New School community can visit the library during open hours. External visitors can schedule an appointment by emailing: MaterialLibrary@newschool.edu. The exhibition will be on view throughout the Spring semester.

To learn more, reference our previous blogs on bio-definitions and the USDA Biopreferred certification.

Read More

Join Our Academic Network

Get Access to our carefully researched and curated academic resources, including model syllabi and webinars. An email from an academic institution or a .edu email address is required. If your academic institution does not use .edu email addresses but you would like to join the network, please contact healthymaterialslab@newschool.edu.

Already have an account? Log in