Why Use Earth Materials?

Buildings made from earth-based materials—raw soil mixed with water, fibers, and additives—have been prevalent for thousands of years. Utilized globally, 30% of the world population today still live in earth-based homes. In the last 150 years, dense solid wall construction has been replaced by cement and concrete because it is cost-effective, fast-drying and durable.

The emergence of cement and concrete building products and efficient construction methods fundamentally changed how we build. Concrete structures are more standardized and less reliant on locally available materials and variable geographies. However, cement contributes at least 8% of global CO2 emissions because of the energy intensive, high-heat processes required to convert minerals into cement binders.

Unfired earthen materials require no heat and little fuel to make them usable and therefore present a significantly lower greenhouse gas-emitting solution to building construction. Unfired Earth materials have lower embodied carbon, passively regulate temperatures, and provide better indoor air quality to living spaces. Research by Lola Ben-Alon (and others) quantifies that earthen walls save 62-71% of embodied energy compared to conventional wall constructions.

Earth home in New Mexico.

Building from Soil

Unlike modern building techniques, earth construction is often context specific and geographically dependent. Each soil type is suitable for a specific application. Soil classification is based on particle size, clay content, organic matter, and mineral content. When fabricating with earth, the type of soil and amount of clay content determines which additional stabilizers are required. Ideally, the earth mixture uses little water, is consistent throughout, and shrinks very little during drying.

Commonly used stabilizers that are less desired are cement and asphalt. Cement is used for strength but is highly carbon intensive, reducing the positive environmental benefits of unfired earth. Asphalt is used for its water repellency, but it is made with bitumen, a by-product of petroleum, which is linked to cancer, a reproductive toxicant and is high in carbon emissions. Alternatively, lime proves to be a more sustainable binder. It sequesters carbon as it cures over many years, and it absorbs toxics from the air. The downside is that it can be slower to dry than cement binders.

Earth blocks made of clay and lime are available from Colorado Earth.

Colorado Earth is currently the only US supplier at scale fabricating compressed earth blocks and adobe with lime. Compressed ECOBLOX by Colorado Earth.

Clay materials can be repaired, reused, and recycled. When mixed with lime, clay materials can be returned to the earth after use.

Local and Natural

Soil is typically best sourced locally to the construction site. Soil from onsite excavation is a particularly good source. The protection of fertile topsoil needs to be considered as a pivotal aspect to minimize harmful interference in the local ecosystem and preserving biodiversity.

Some earth-building material production companies are sourcing soil from quarries local to their production facilities to standardize mixes and achieve higher quantities of materials.

Fibrous materials are added for additional reinforcement. The exact material additive depends upon what is locally available, like straw or other agricultural byproducts. Working with earth materials connects construction practices with local landscapes.

For best results, it is important to consult natural builders who have expertise in best practices. To accelerate the growth and adoption of earth-based building practices, contractors will need education on earth-building techniques based on a combination of historical knowledge and new technologies. Earth fabrication supports the growth of skilled masonry labor and revives vital understanding of how to work with local landscapes.

“By working directly with the site as material, a larger connection to the immediate landscape and place is made. The earthen construction process continuously reveals the unseen layers and history of the site. Sifting, sorting, soaking, and weighing soils create a method of engagement and experience of site” -Catherine Page Harris and Charlie O’Geen of Poured Earth Collaborative

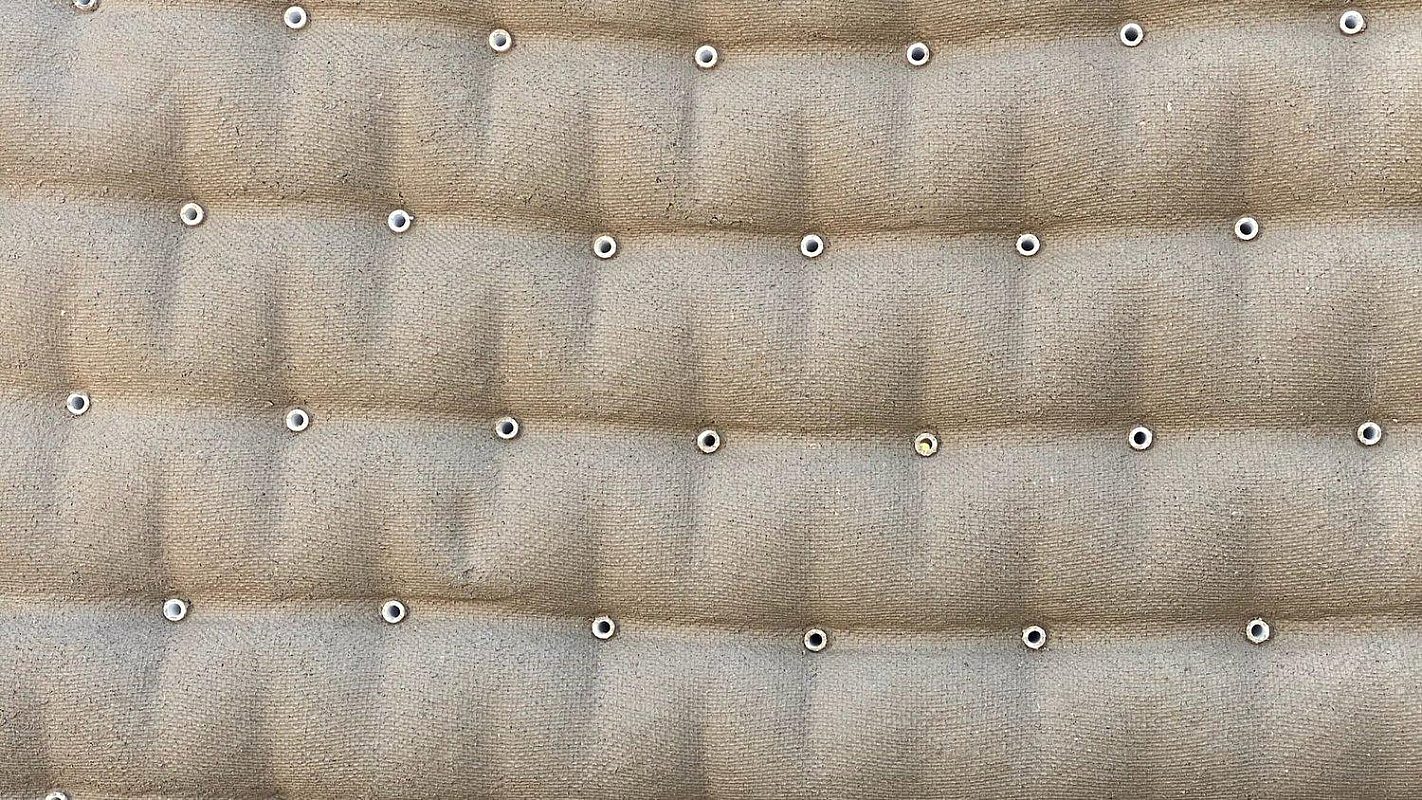

Research by the Poured Earth Collaborative on fabric formed poured earth™.

"The earthen construction process continuously reveals the unseen layers and history of the site." -Catherine Page Harris and Charlie O'Geen

Performance and Policy

Tackling the perceptions of the efficacy of earth materials is a current challenge. Traditional earth construction techniques often lack policy and testing results compared with conventional building practices. Few states in the US include earth construction in their building codes. The few policies that exist, such as the 2021 New Mexico Earth Building Materials Code, provide guidelines for builders who want to implement earth building practices. Research and testing is currently underway to achieve compressive and tensile strength levels suitable for modern building code compliance.

Earth Construction Techniques

Adobe EcoBlox by Colorado Earth. Adobe blocks are made by mixing muddy soil with fiber and drying it within a formwork.

Compressed Earth Blocks by Native Earth. Compressed Earth Blocks are made in a mold with applied pressure and an added soil stabilizer.

Structural Rammed Earth by Sirewall. In Rammed Earth fabrication, soil, sand and aggregate are compacted layer by layer into a formwork.

Loma™ Plasters by American Clay are a mix of natural earth and pigment.

Earth materials can be applied in various well-proven techniques, such as Adobe, Rammed Earth, Compressed Blocks, Cob, Wattle + Daub, and Light Straw Clay. Current research is testing 3D printing, bio-based additives, and a range of fibrous byproduct materials to achieve higher performance. Consult with regional knowledgeable natural builders to understand which earth technique is best suited for your location and which materials are locally available.

Refer to our Earth Material Collection to learn more about scaled products.

Thanks to Lola Ben-Alon at Natural Materials Lab for contributing research insights.

Read More

Join Our Academic Network

Get Access to our carefully researched and curated academic resources, including model syllabi and webinars. An email from an academic institution or a .edu email address is required. If your academic institution does not use .edu email addresses but you would like to join the network, please contact healthymaterialslab@newschool.edu.

Already have an account? Log in